Braskem Takes Polypropylene to the Next Level of Performance in Partnership with WEAV3D® utilizing its Rebar for Plastics® Lattice Technology

IMPROVING NATURAL-FIBER REINFORCED POLYPROPYLENE

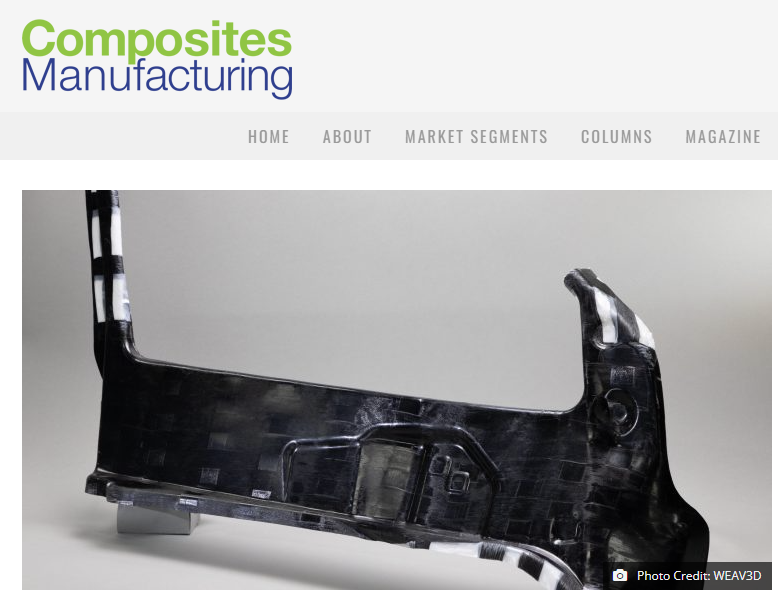

This solution combines Braskem’s polypropylene sheets with WEAV3D lattice technology to address new structural and automotive applications requiring high-strength, lightweight material solutions

Braskem to present its PP solutions with WEAV3D lattice technology at the 2023 SPE® TPO Global Automotive Conference in Detroit, October 1-4

WEAV3D Awarded National Science Foundation Grant for Natural Fiber Polypropylene Enhancements

Newsroom

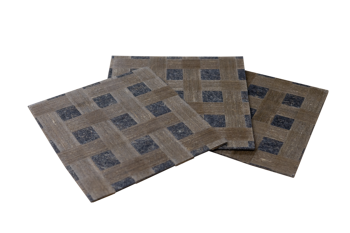

NORCROSS, Ga., March 13, 2023 — WEAV3D Inc., an innovator in composite materials, manufacturing processes and processing equipment, has been awarded a $200,000 Technology Enhancement for Commercial Partnerships (TECP) supplement to its 2021 National Science Foundation (NSF) Small Business Innovation Research (SBIR) Phase II grant. The new award focuses on the use of WEAV3D’s woven composite lattices to enhance the performance and sustainability of natural fiber polypropylene (NFPP) composites for automotive applications.

“This grant will fund a detailed study of mechanical performance and manufacturability of lattice-reinforced NFPP panels, including the development and validation of finite element simulation tools,” says Chris Oberste, President of WEAV3D and Principal Investigator for this award. “Our technology enhances the performance of NFPP materials, enabling these sustainable materials to be optimized for a wide range of applications within the vehicle.”

Antolin, one of the largest international suppliers for automotive interiors and a leader in innovation and sustainability, is the commercial partner for the TECP award. “The use of WEAV3D reinforcements promises to reduce the weight of our NFPP components, which in turn reduces CO2 emissions and trims waste to improve the overall sustainability of these parts,” says Pablo Soto, Materials Specialist with Antolin’s Corporate Innovation Department. This supports Antolin’s sustainability commitments to reduce CO2 emissions by 75 percent and nonhazardous waste generation by 10 percent by 2028.

Polyvlies, a leading supplier of nonwoven materials, is also participating in the project. The company’s Naroplast® thermoplastic natural fiber composite targets automotive compression molding applications. “WEAV3D’s ability to tailor the tapes and woven patterns to the application provides an extremely flexible way to increase the strength and stiffness of the panels while improving the design flexibility,” says Axel Hinrichs, CEO of Polyvlies USA.

This additional award follows a previous $1 million grant to fund the design, fabrication and testing of a continuous composite forming line that uses ultrasonic welding to increase the production throughput of WEAV3D’s patent-pending continuous composite forming process. This next-generation system is being built according to automotive production speed and quality standards, with a target production capacity of 200,000 to 300,000 automotive door panel size parts per year per machine.

For more information visit: weav3d.com and grupoantolin.com.

About WEAV3D Inc.

Headquartered in metro Atlanta, Ga., WEAV3D is an innovator in composite materials, manufacturing processes, and processing equipment, having spun out of the Georgia Institute of Technology in 2017. WEAV3D’s patented composite forming technology integrates weaving and composite consolidation into an automated, continuous process that reduces waste, cycle times and material handling costs. When combined with injection overmolding, thermocompression, or thermoforming, this novel Rebar of Plastics® approach improves part stiffness and strength while minimizing weight, enabling new innovations in the automotive and construction markets at a fraction of the cost and cycle time associated with traditional composite manufacturing.

About Antolin

Antolin is one of the largest manufacturers of vehicle components in the world and a global supplier of technological solutions for automotive interiors. The company supplies the world’s leading car manufacturers through 140 factories in 26 countries. Antolin has 25,000 employees and sales of €4,055 million in 2021. Antolin offers high added value products via five Business Units: Overheads; Doors & Hard Trim; IPs & Central Consoles; Components & JITs BU; and Lighting, HMI & Electronics.

About Polyvlies

Founded in 1850 by Swibertus Beyer, Polyvlies developed into a major leader in the area of

technical nonwovens. With manufacturing across Europe and in Winston-Salem, Polyvlies has

500 employees with an annual sales volume of $110 million. Polyvlies’ capabilities span from

natural fiber to glass fiber nonwovens, consolidated as well as unconsolidated and

thermoformed products.

About the NSF’s Small Business Programs

America’s Seed Fund powered by NSF awards $200 million annually to startups and small businesses, transforming scientific discovery into products and services with commercial and societal impact. Startups working across almost all areas of science and technology can receive up to $2 million to support research and development (R&D), helping de-risk technology for commercial success. America’s Seed Fund is congressionally mandated through the Small Business Innovation Research (SBIR) program. The NSF is an independent federal agency with a budget of about $8.5 billion that supports fundamental research and education across all fields of science and engineering. For more information, visit seedfund.nsf.gov.

WEAV3D Brings Its Composite Production Technology to Upcoming Plug and Play Program

Newsroom

Norcross, GA, October 02, 2019 — WEAV3D, an innovator in composite materials, manufacturing processes and processing equipment, was recently selected by Plug and Play to participate in its Winter 2019 Mobility accelerator program, which focuses on emerging automotive technologies. WEAV3D returns to Plug and Play after graduating from its Spring 2019 Materials and Packaging program.

Designed for high volume production, WEAV3D’s composite forming machine processes continuous, fiber-reinforced thermoplastic tapes, allowing users to vary weave pattern, lattice density and tape-type and enabling complete control over part cost, strength, and stiffness. Lattice structures are combined with injection molding or thermoforming processes—creating lightweight structural composites that cost up to 50 percent less than composites formed using traditional methods.

WEAV3D’s structural composite technology is an excellent fit for the automotive industry, as it reduces weight while maintaining high-strength components in vehicles. While this area has been the company’s initial focus, the technology applies more broadly to other structural composites applications as well.

Plug and Play’s three-month business development programs—which also include Materials and Packaging, Energy, Sustainability, Construction and more—consist of various workshops, mentor meetings and networking events. As part of the Winter 2019 batch, WEAV3D will graduate this December at the Winter Summit, where all 130 startups will make onstage pitches in front of over 500 investors and other industry leaders.

To learn more about WEAV3D, visit www.weav3d.com.

###

About WEAV3D Inc.

WEAV3D Inc. is an innovator in composite materials, manufacturing processes and processing equipment. Headquartered in Norcross, GA, they originated as a technology startup within the Materials Science and Engineering department at the Georgia Institute of Technology. The patent-pending WEAV3D composite forming process enables the production of optimized lattice structures that can be combined with injection molding or thermoforming processes to create lightweight structural composite parts at a fraction of the cost and cycle time associated with traditional composite manufacturing. These innovations enable companies in industries such as automotive, aircraft, wind turbines and cargo transportation to produce parts that are lighter, stronger and less expensive.