ASME 2024 Aerospace Structures, Structural Dynamics, and Materials Conference

A Multiscale Approach to the Design and Analysis of WEAV3D Lattice Structures

Altair Vice President of Composite Technology & Aerospace Strategy, Jeffrey A. Wollschlager presents “A Multiscale Approach to the Design and Analysis of WEAV3D Lattice Structures” at the ASME 2024 Aerospace Structures, Structural Dynamics, and Materials Conference.

ANTEC 2024 - Cost-Effective Automotive Body Structures

ANTEC 2024 - Cost-Effective Automotive Body Structures

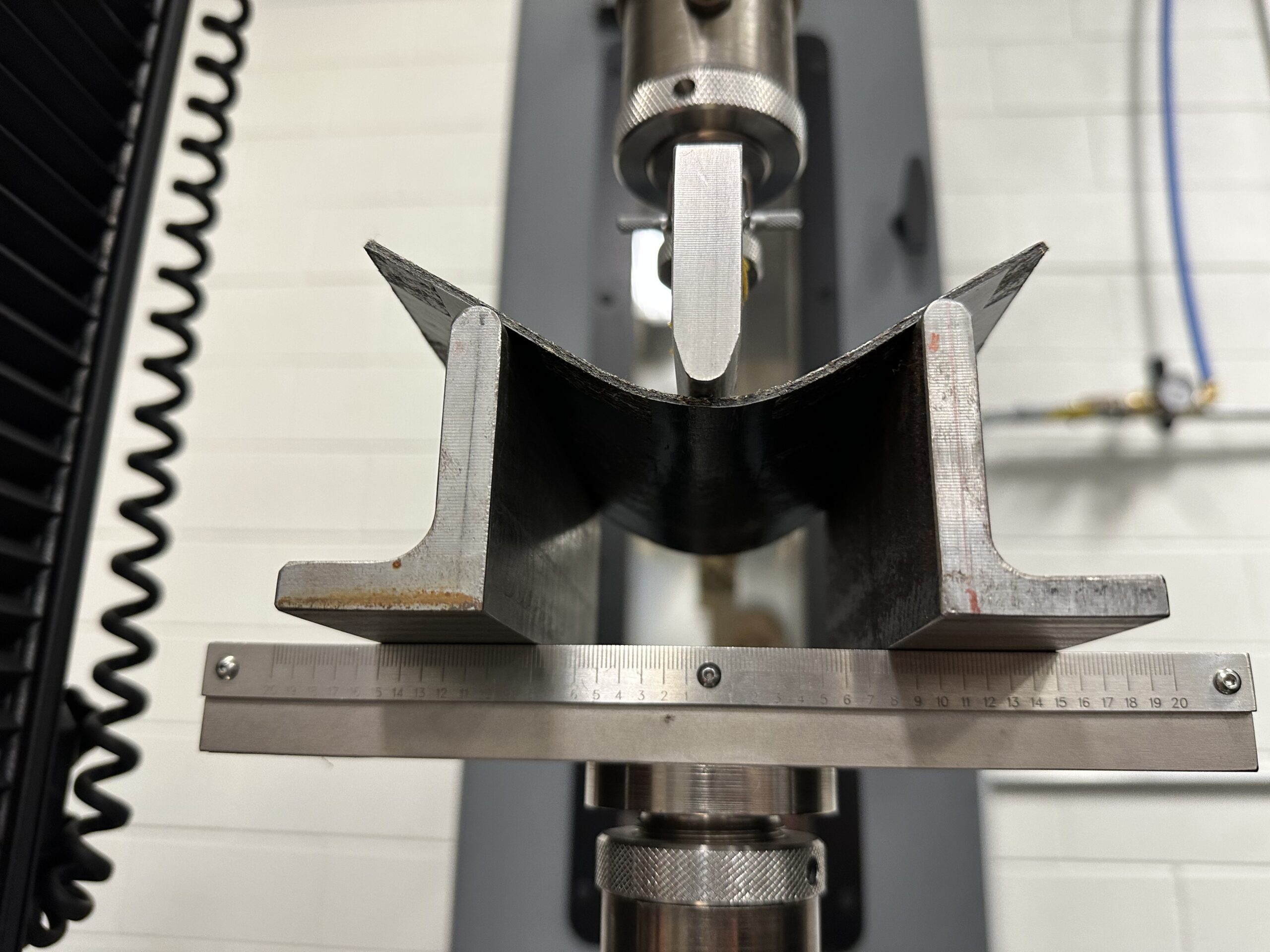

WEAV3D has developed a novel hybrid-material approach, Rebar for Plastics®, that combines existing thermoforming, compression molding or injection overmolding processes with woven composite lattices formed from unidirectional thermoplastic tapes to produce high-volume, low-cost structural composites. The resulting structural panel exhibits high stiffness, strength, and ductility, equivalent or better than sheet metal, while offering weight savings of up to 65% compared to steel.

In partnership with Braskem, Altair, and the Clemson Composites Center, an automotive door structure originally developed in carbon fiber/PA6 organosheet was redesigned as a lattice reinforced polypropylene panel. This highly optimized structure achieved 20% weight savings and 50% cost savings vs. the original organosheet, while also reducing trim scrap mass by 63%. The FEA design process and experimental results will be presented, as well as a cost and performance comparison against the original organosheet design.

Braskem and WEAV3D® Announced as Finalists for JEC Composites Innovation Awards 2024

Braskem and WEAV3D® Announced as Finalists for JEC Composites Innovation Awards 2024

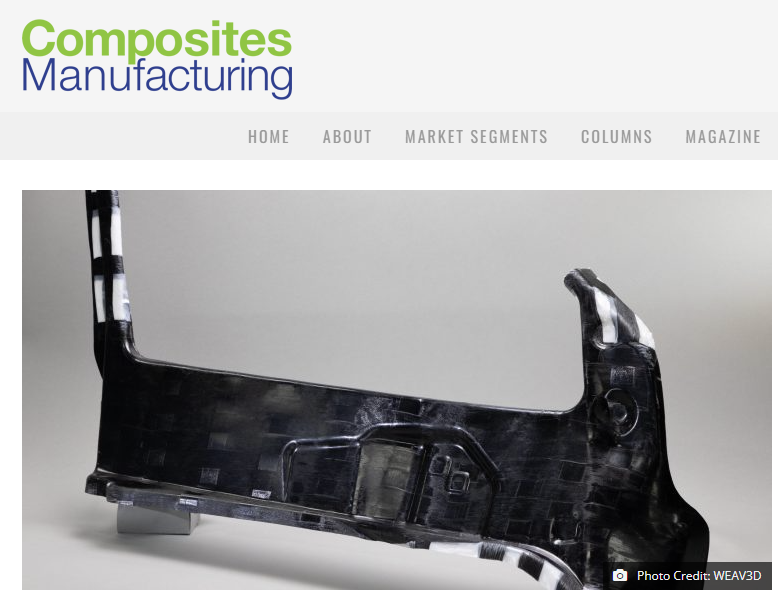

Cost-effective automotive door body structure demonstrator part made from Braskem polypropylene and WEAV3D lattice technology receives industry recognition for a novel approach.

Braskem and WEAV3D automotive component to showcase at the 2024 JEC World trade show in Paris, France, March 5-7, 2024.

Rebar for Plastics: Enabling Cost Effective Body Structures

Rebar for Plastics: Enabling Cost Effective Body Structures

In partnership with Braskem, Altair, and the Clemson Composites Center, an automotive door structure originally designed in carbon fiber/PA6 organosheet was redesigned utilizing WEAV3D’s Rebar for Plastics® design methodology, which leverages various micro-and macro-mechanical concepts to maximize performance and minimize cost in hybrid length-scale composites. This highly optimized structure achieved 20% weight savings and 50% cost savings vs. the original organosheet, while also reducing trim scrap mass by 63%.