SPE Automotive Composites Conference & Exhibition 2025

SPE ACCE 2025 - Efficient Simulation for Hybrid Overmolded Composite Lattice Structures: A Combined Implicit and Explicit FEA Approach

WEAV3D presents an Efficient Simulation for Hybrid Overmolded Composite Lattice Structures: A Combined Implicit and Explicit FEA Approach at SPE ACC 2025.This paper presents a hybrid workflow: multiscale modeling enables quick stiffness evaluation and guide design iteration, while discrete modeling is applied to critical designs for detailed stress and strain analysis. The hybrid workflow is demonstrated on a heavy truck component to illustrate how the combined approach improves computational efficiency in part-level analysis of lattice-reinforced composites.

SPE Automotive Composites Conference & Exhibition 2025

SPE ACCE 2025 - Paper Composites reinforced with GFPP or NFPP Lattices

WEAV3D’s President and Chief Engineer – Chris Oberste – presents Paper Composites Reinforced with GFPP or NFPP Lattices in conjunction with the University of Tennessee Knoxville and Volkswagen at SPE Automotive ACCE Conference 2025.

SPE Automotive Composites Conference & Exhibition 2024

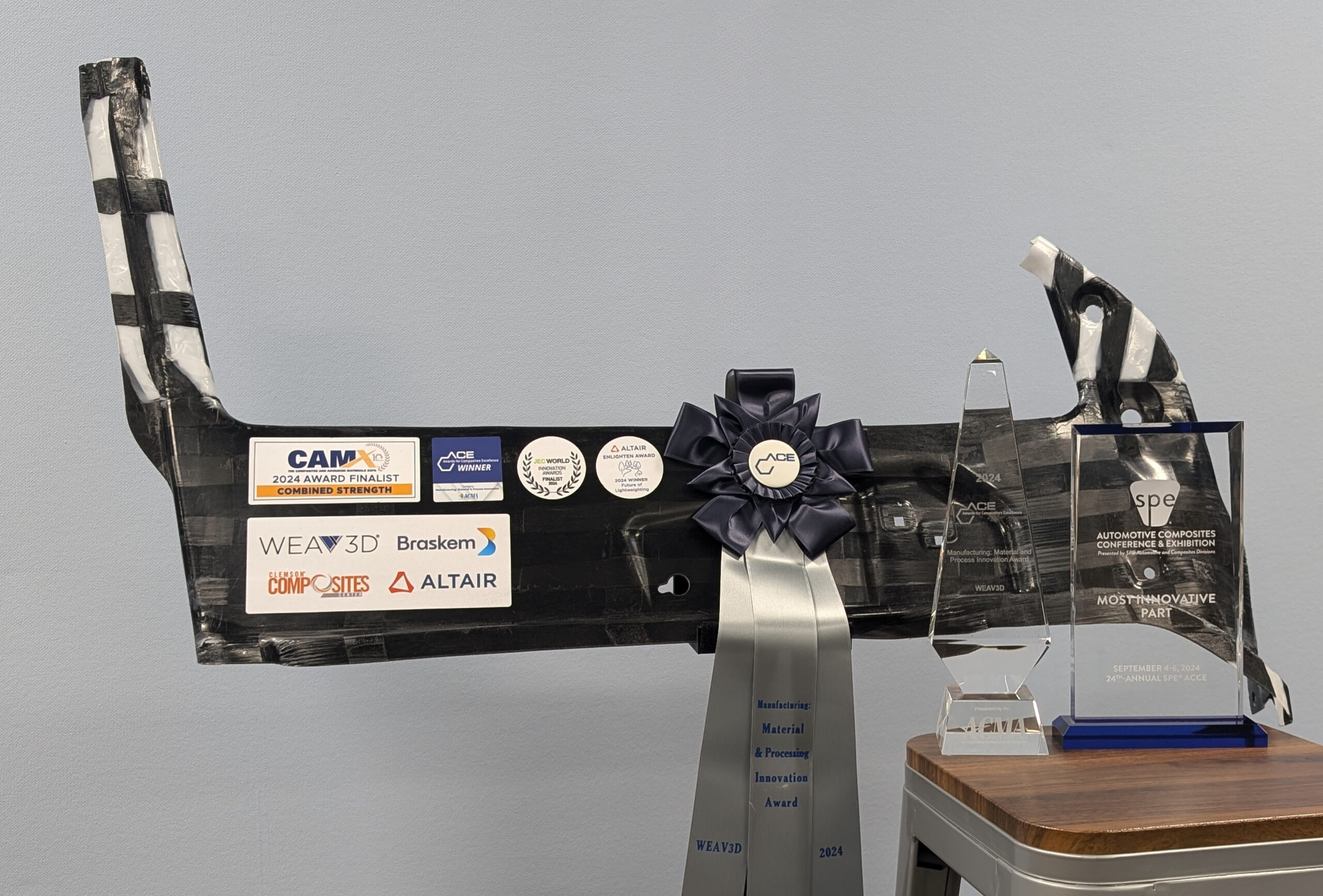

SPE ACCE 2024 - Cost Effective Thermoplastic Body Structures

WEAV3D has developed a novel hybrid-material approach, Rebar for Plastics®, that combines existing thermoforming, compression molding or injection overmolding processes with woven composite lattices formed from unidirectional thermoplastic tapes to produce high-rate, cost-effective structural composites. The resulting structural panel exhibits high stiffness, strength, and ductility, equivalent or better than sheet metal, while offering weight savings of up to 65% compared to steel. In partnership with Braskem, Altair, and the Clemson Composites Center, an automotive door structure originally developed in carbon fiber/PA6 organosheet was redesigned as a lattice reinforced polypropylene panel. A case study covering design, manufacturing, and testing of this innovative thermoplastic composite structure will be presented, showcasing 20% weight savings and 50% cost savings vs. organosheet, while also reducing trim scrap mass by 63%. This presentation will also discuss how OEMs and Tier suppliers can adapt this cost-effective lattice-reinforced approach to other vehicle components and molding processes.

SPE Automotive Composites Conference & Exhibition 2024

SPE ACCE 2024 - Composite Lattice Reinforced Part Optimization with FEA: An Automotive Door Component Case Study

This paper presents a finite element analysis (FEA) method of modelling automotive components reinforced with WEAV3D composite lattice structures. WEAV3D Inc. has developed a novel hybrid-material approach, Rebar for Plastics®, merging existing thermoforming, compression molding or injection overmolding processes with woven composite lattices formed from unidirectional thermoplastic tapes to produce high-rate, cost-effective structural composites. These materials pose challenges for conventional composite FEA modeling, demanding advanced techniques for accurate mechanical predictions, especially in structural applications.

Presented FEA methodology addresses these challenges by enabling explicit modeling of lattice designs using Altair HyperMesh. By parameterizing tape materials, spacing, and layer count through scripting, the methodology streamlines design exploration, eliminating the need for CAD models for each iteration and enabling regional optimization within the part. This optimizes lattice structures efficiently to achieve desired mechanical properties at the part level.

Through a case study of an automotive door component, we demonstrate the applicability of our FEA workflow. Comparison of FEA predictions with experimental data validates the reliability of the model. These results highlight the efficacy of our methodology in predicting mechanical behavior, suggesting its potential to guide design decisions across various industrial applications through optimization.