WEAV3D® technology combines weaving and composite consolidation into an automated, continuous process that reduces waste, cycle time and material handling costs—enabling new innovations in the automotive, construction and transportation industries.

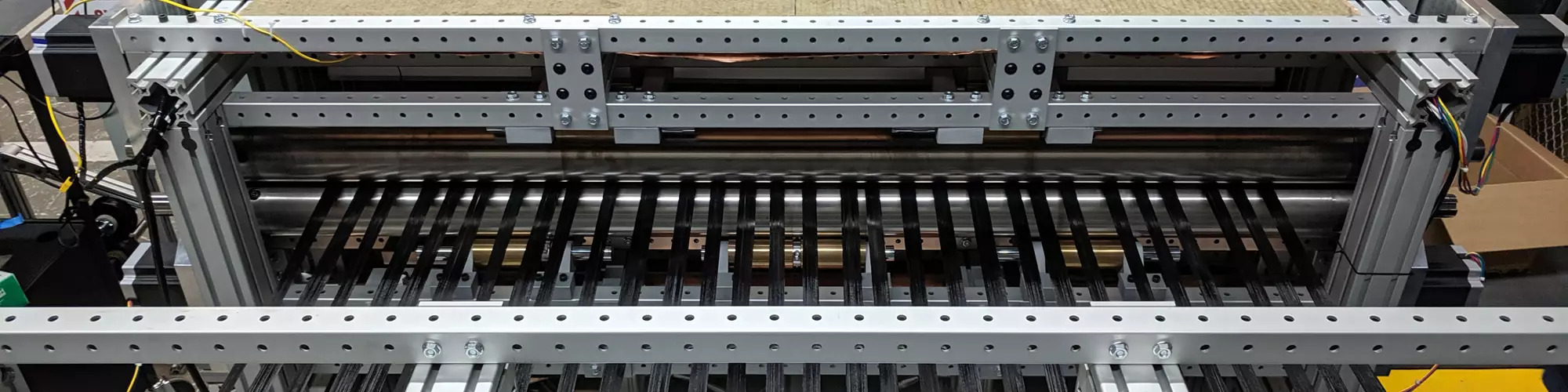

Process

The patented WEAV3D® process is based on a woven composite lattice reinforcement called Rebar For Plastics®. Our lattice forming machines produce custom lattice structures from unidirectional, fiber-reinforced composite tapes. The composite lattices are then overmolded into a finished structural component using conventional molding processes.

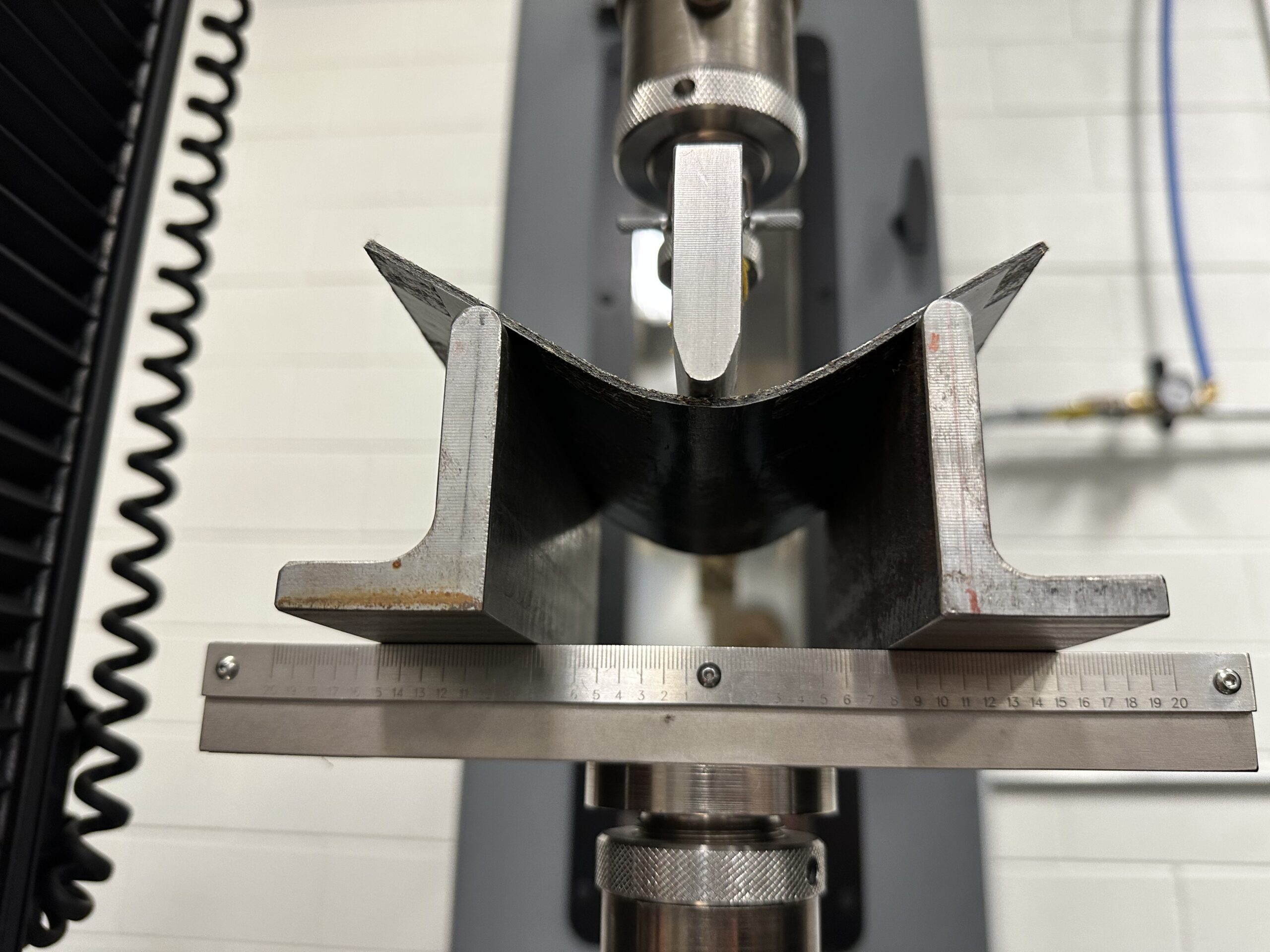

Mechanical Properties

By tuning the weave density, tape materials and number of layers in the lattice preform, we can locally tune a part's performance to meet application-specific targets. This ability to selectively increase the strength and stiffness of components opens up new design possibilities and reduces costs by 30 to 50% versus traditional composites.

Automotive

Lightweight structural composites are a key enabling technology as the automotive industry drives toward more fuel-efficient vehicles. Our patent pending reinforcement materials allow you to lightweight automotive interior and exterior components, including instrument and body panels—increasing vehicle fuel economy and extending EV range.

Construction

Our composite lattice is an alternative solution to traditional steel wire cage, rebar and sheet molding compound (SMC) reinforcement for precast polymer concrete. It offers a lightweight, completely non-metallic reinforcement material that provides high levels of durability and strength, as well as resistance to corrosion and other environmental conditions.

Recent Technology News

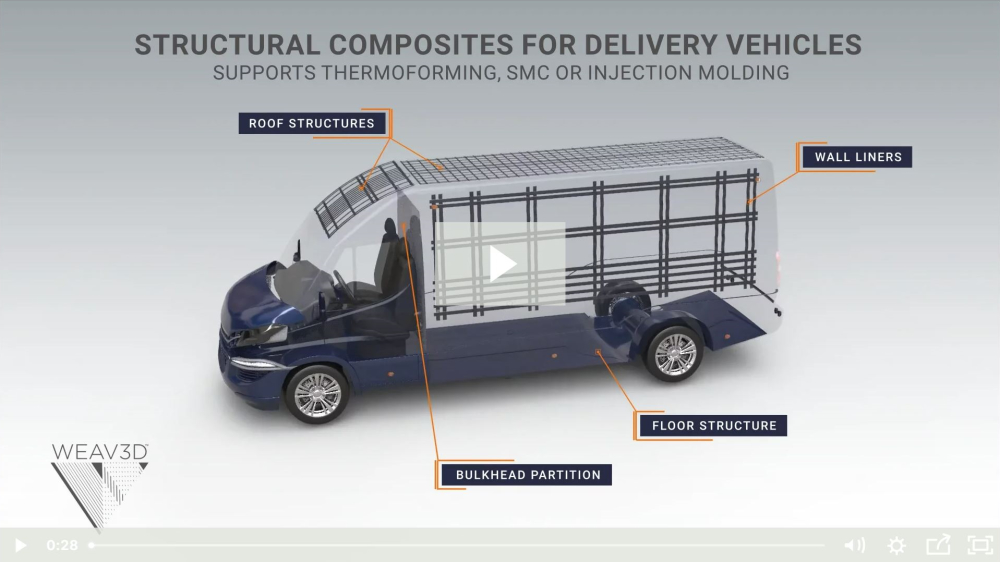

Advanced Commercial Delivery Vehicle Reinforcements

Our woven composite lattice technology can boost the fuel economy of commercial delivery…

Improving Natural-Fiber Reinforced Polypropylene

Natural-fiber reinforced thermoplastic composites have recently emerged as a lightweight,…

New CompositesWorld Article Explores Our Technology in High-Volume Applications

We're excited to announce we were recently featured in CompositesWorld, a leading source…